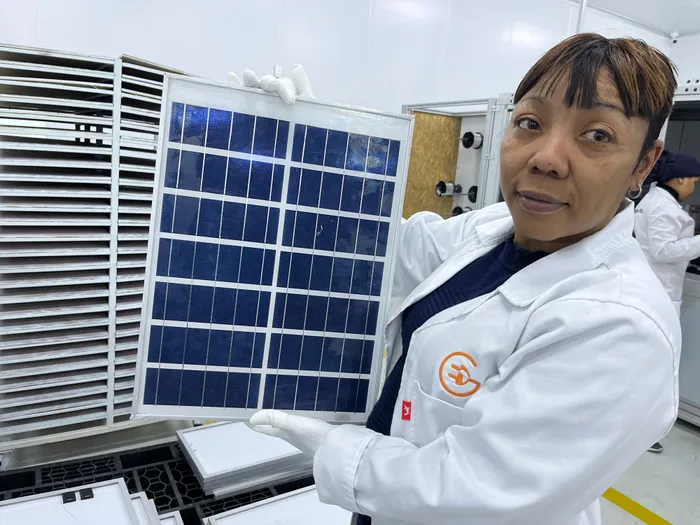

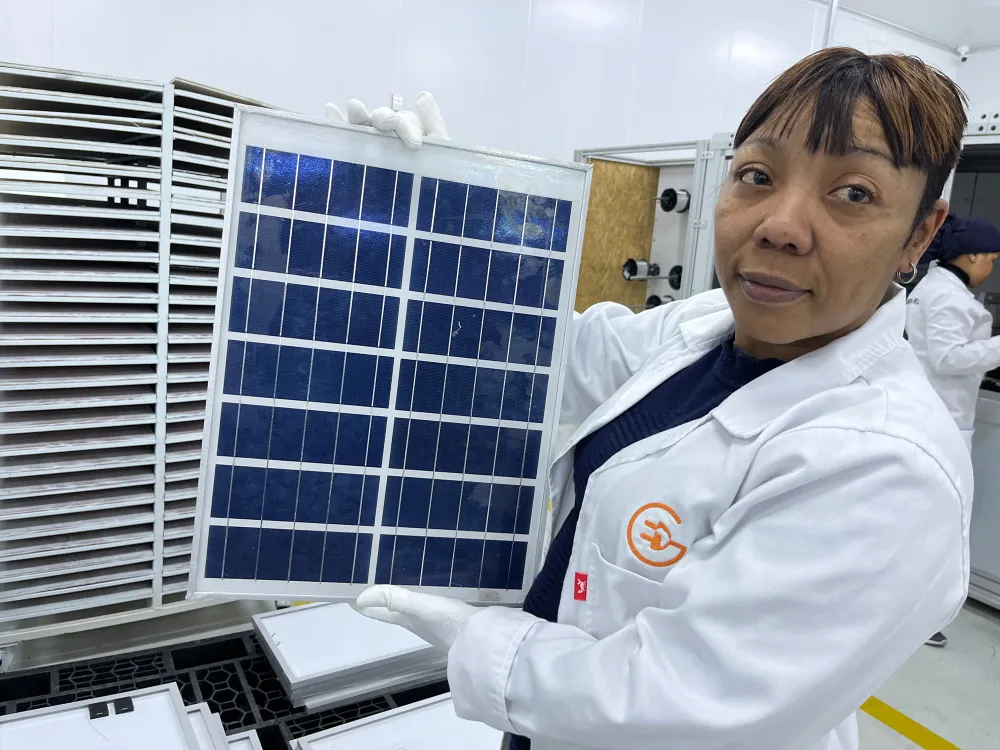

René Salmon, 46, from Beacon Valley, leads the all-women solar panel manufacturing facility at Ener-G-Africa’s (EGA) based in Ndabeni.

Grandmothers, mothers and daughters are proud to be assembling solar panels and being pioneers in threading cells together, which convert energy from the sun into electricity.

Kelly Rabagadie, 25, from Bonteheuwel, who solders parts of the solar panels together, said it means a lot to her to be able to be assembling something that she knew nothing about months ago.

“I had to Google, when my aunt offered me this opportunity of employment,” she said. “I’m proud of myself. This is just the beginning for me. I started learning to assemble 20-watt panels and now we’re doing more complicated panels of 50 watts,” she said.

Ms Rabagadie said the income has helped her to put food on the table for her and her mom.

Her aunt, former South African National Defence Force (SANDF) captain René Salmon, 46, from Beacon Valley, leads the all-women solar panel manufacturing facility at Ener-G-Africa’s (EGA), in Ndabeni.

The plant is a first-of-its-kind, as it is the only small solar panel plant in the world certified by TUV Rheinland, a German-accredited inspection authority.

The 800m² plant manufactures 20-watt panels that sell for around R300 each in South Africa, Malawi, Angola, Mozambique, Zimbabwe, and several other African countries.

Ms Salmon was one of five women who were trained in assembling solar panels in July last year.

Her basic military instructor, Captain André Moolman, co-founder and chief executive officer of Ener-G-Africa’s (EGA), called Ms Salmon to lead the 37-women member crew.

The all-woman plant is Mr Moolman’s brainchild.

EGA engineers train the core group of women, who serve as supervisors, machine operators and quality checkers. Once they have mastered their skills they then train other women. These women are either recruited internally or as casuals by submitting their curriculum vitae.

“We look for women willing to learn; the work is physical, and you need attention to detail,” said Ms Salmon.

She said a woman’s delicate touch, attention to detail, neatness and accuracy were crucial in assembling these much-needed panels.

Ms Salmon explained that the parts were “very sensitive to touch” including the cells made from silicon, which could shatter if not handled correctly.

It is the top layer covering the upper, sun-facing side, of photovoltaic module. It is passive but a critical part of a solar cell.

She said each of the five women had to bring another woman “with a can do spirit” to grow the team.

“A lot of what I do at EGA I draw from my experience in the defence force. Solar panel technology was completely new for me; I learned as I went and I'm still learning.

“We have battle scars of soldering irons and cuts from the corners of sharp aluminium frames, but we’ve all learned so much from this experience,” she said.

Grandmother Shirley Swartz, 44, from Delft, said: “Never in my life did I think that I would make solar panels.”

She is a former SANDF member and had worked in the plant’s manufacturing division, where they make energy-efficient biomass cooking stoves of which four million have been distributed across Africa.